Compact hexapod microrobot, direct drive, 12.5 mm/s, 2.5 kg load, vacuum-compatible to 10-6 hPa, D-sub connector, cable set 2 m vacuum side, feedthrough. Air-side connecting cables are not included in the scope of delivery and must be ordered separately.

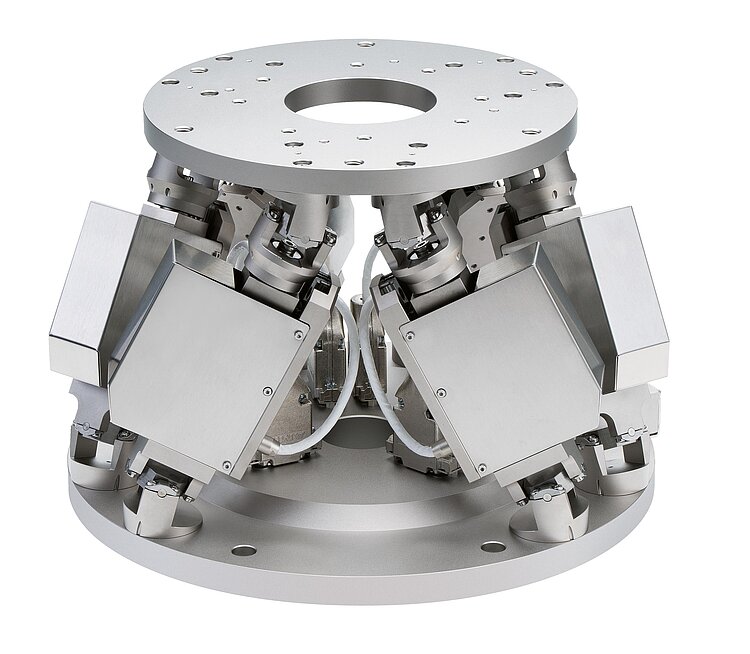

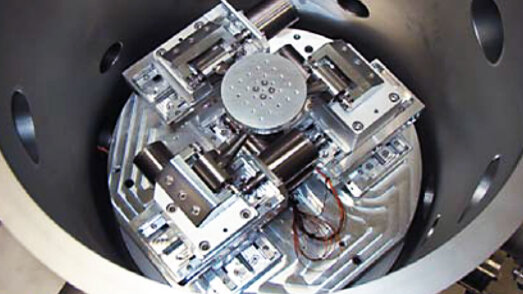

H-824.V Vacuum-Compatible 6-Axis Hexapod

Compact and Precise

- Load capacity to 5 kg, self-locking version

- Travel ranges to 45 mm / 25°

- Minimum incremental motion to 0.3 µm

- Repeatability to ±0.1 µm / ±2 µrad

- Velocity to 12.5 mm/s

Precision-class 6-axis positioning system

Parallel-kinematic design for six degrees of freedom, making it significantly more compact and stiff than serial-kinematic systems, higher dynamics, no moved cables: Higher reliability, reduced friction. suitable for vacuum environments to 10-6 hPa.

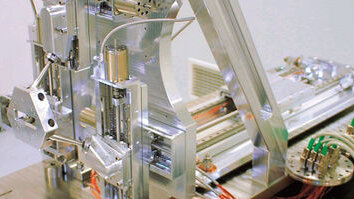

Compact due to folded drive design

PIVirtualMove

The simulation software simulates the limits of the workspace and load capacity of a hexapod. Therefore, even before purchasing, you can check whether a particular hexapod model can handle the loads, forces, and torques occurring in an application. For this purpose, the simulation tool takes the position and motion of the hexapod as well as the pivot point and several reference coordinate systems into account.

Application fields

Industry and research. For micromanipulation, biotechnology, semiconductor manufacturing

Specifications

Specifications

| Motion | H-824.D2V | H-824.G2V | Tolerance |

|---|---|---|---|

| Active axes | X ǀ Y ǀ Z ǀ θX ǀ θY ǀ θZ | X ǀ Y ǀ Z ǀ θX ǀ θY ǀ θZ | |

| Travel range in X | ± 22.5 mm | ± 22.5 mm | |

| Travel range in Y | ± 22.5 mm | ± 22.5 mm | |

| Travel range in Z | ± 12.5 mm | ± 12.5 mm | |

| Rotation range in θX | ± 7.5 ° | ± 7.5 ° | |

| Rotation range in θY | ± 7.5 ° | ± 7.5 ° | |

| Rotation range in θZ | ± 12.5 ° | ± 12.5 ° | |

| Maximum velocity in X | 12.5 mm/s | 0.5 mm/s | |

| Maximum velocity in Y | 12.5 mm/s | 0.5 mm/s | |

| Maximum velocity in Z | 12.5 mm/s | 0.5 mm/s | |

| Maximum angular velocity in θX | 135 mrad/s | 5.5 mrad/s | |

| Maximum angular velocity in θY | 135 mrad/s | 5.5 mrad/s | |

| Maximum angular velocity in θZ | 135 mrad/s | 5.5 mrad/s | |

| Typical velocity in X | 5 mm/s | 0.2 mm/s | |

| Typical velocity in Y | 5 mm/s | 0.2 mm/s | |

| Typical velocity in Z | 5 mm/s | 0.2 mm/s | |

| Typical angular velocity in θX | 28 mrad/s | 2.3 mrad/s | |

| Typical angular velocity in θY | 28 mrad/s | 2.3 mrad/s | |

| Typical angular velocity in θZ | 28 mrad/s | 2.3 mrad/s | |

| Positioning | H-824.D2V | H-824.G2V | Tolerance |

| Minimum incremental motion in X | 2 µm | 0.3 µm | typ. |

| Minimum incremental motion in Y | 2 µm | 0.3 µm | typ. |

| Minimum incremental motion in Z | 1 µm | 0.3 µm | typ. |

| Minimum incremental motion in θX | 12 µrad | 3.5 µrad | typ. |

| Minimum incremental motion in θY | 12 µrad | 3.5 µrad | typ. |

| Minimum incremental motion in θZ | 14 µrad | 3.5 µrad | typ. |

| Unidirectional repeatability in X | ± 0.5 µm | ± 0.4 µm | typ. |

| Unidirectional repeatability in Y | ± 0.5 µm | ± 0.4 µm | typ. |

| Unidirectional repeatability in Z | ± 0.15 µm | ± 0.1 µm | typ. |

| Unidirectional repeatability in θX | ± 3 µrad | ± 2 µrad | typ. |

| Unidirectional repeatability in θY | ± 3 µrad | ± 2 µrad | typ. |

| Unidirectional repeatability in θZ | ± 2.5 µrad | ± 3 µrad | typ. |

| Backlash in X | 3 µm | 5 µm | typ. |

| Backlash in Y | 3 µm | 5 µm | typ. |

| Backlash in Z | 1.5 µm | 1.5 µm | typ. |

| Backlash in θX | 20 µrad | 30 µrad | typ. |

| Backlash in θY | 20 µrad | 30 µrad | typ. |

| Backlash in θZ | 60 µrad | 45 µrad | typ. |

| Drive Properties | H-824.D2V | H-824.G2V | Tolerance |

| Drive type | DC motor | DC gear motor | |

| Nominal voltage | 24 V | 24 V | |

| Mechanical Properties | H-824.D2V | H-824.G2V | Tolerance |

| Stiffness in X | 1.7 N/µm | 1.7 N/µm | |

| Stiffness in Y | 1.7 N/µm | 1.7 N/µm | |

| Stiffness in Z | 7 N/µm | 7 N/µm | |

| Maximum load capacity, base plate in any orientation | 1.25 kg | 2.5 kg | |

| Maximum load capacity, base plate horizontal | 2.5 kg | 5 kg | |

| Maximum holding force, base plate in any orientation | 5 N | 25 N | |

| Maximum holding force, base plate horizontal | 15 N | 50 N | |

| Overall mass | 8 kg | 8 kg | |

| Material | Aluminum | Aluminum | |

| Miscellaneous | H-824.D2V | H-824.G2V | Tolerance |

| Operating temperature range | -10 to 50 °C | -10 to 50 °C | |

| Vacuum class | 10⁻⁶ ǀ hPa | 10⁻⁶ ǀ hPa | |

| Maximum bakeout temperature | 80 °C | 80 °C | |

| Connector for data transmission | HD D-sub 78 (m) | HD D-sub 78 (m) | |

| Connector for supply voltage | LEMO | LEMO | |

| Cable length | 2 m | 2 m | |

| Recommended controllers / drivers | C-887.5x | C-887.5x |

Technical data specified at 22±3 °C.

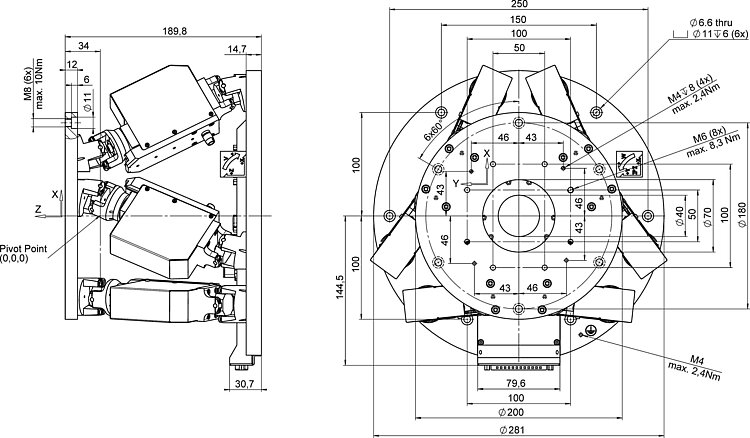

The maximum travel ranges of the individual coordinates (X, Y, Z, θX, θY, θZ) are interdependent. The data for each axis shows its maximum travel range when all other axes are in the zero position of the nominal travel range and the default coordinate system is in use, or rather when the pivot point is set to 0,0,0.

For continuous operation in a vacuum, restrictions on operating parameters may be necessary due to heat generation.

Air-side connecting cables are not included in the scope of delivery and must be ordered separately.

Ask about customized versions.

Downloads

Product Note

Datasheet

Documentation

User Manual MS200

H-824 Compact Microrobot

3-D Models

H-824.x2x 3-D model

Software Files

PIVirtualMove

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

Compact hexapod microrobot, gearhead, 0.5 mm/s, 5 kg load, vacuum-compatible to 10-6 hPa, D-sub connector, cable set 2 m vacuum side, feedthrough. Air-side connecting cables are not included in the scope of delivery and must be ordered separately.

Ask an engineer!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.

Technology

EtherCAT Connectivity of PI Products

PI offers high-precision drives for use as EtherCAT slave, or integrates with ACS Motion Controllers as Master, or 2nd Master in an existing architecture.

Vacuum

Careful handling, adequate premises: PI does not only have the necessary equipment for the qualification of materials, components and final products, but also has many years of experience with regard to HV und UHV positioning systems.

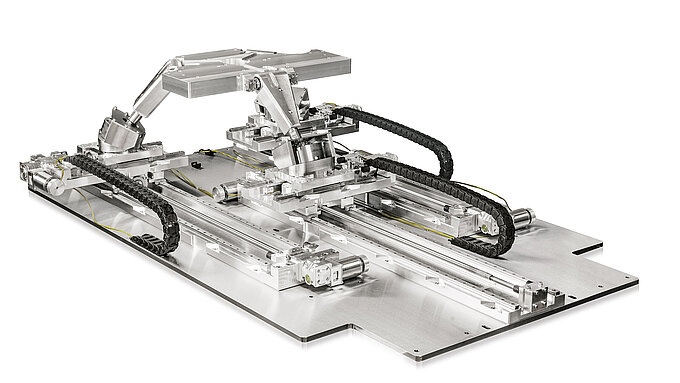

Multi-Axis Positioners

Hexapod platforms are used for precision positioning and alignment of loads in all six degrees of freedom, three linear axes, and three rotational axes.

Applications

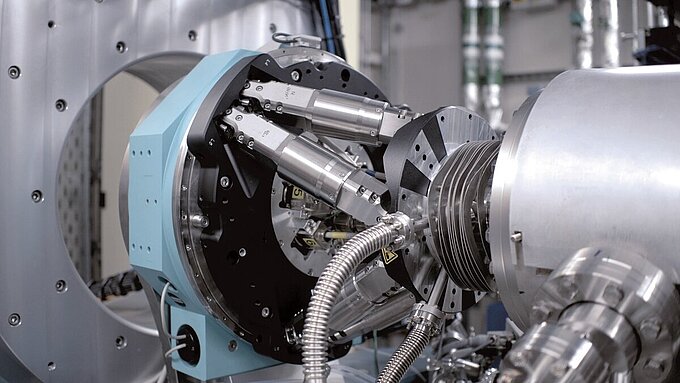

Multi-Axis Beam Preparation

Sample Adjustment

At Diamond Light Source, UK, beamline I07 is a high-resolution X-ray diffraction beamline dedicated to investigate the structure of surfaces and interfaces.

Sample Positioning in High-Vacuum

Sample Manipulators in High-Vacuum

Optics Hutch Instrumentation

At DESY in Hamburg, the P05 Imaging Beamline is operated by the HZG.