Vacuum-compatible precision linear stage; 2-phase stepper motor; 26 mm travel range; 100 N load capacity; 10 mm/s maximum velocity; ball screw; vacuum compatible to 10⁻⁶ hPa

L-509 V6 • V7 • V9 Vacuum-Compatible Precision Linear Stage

Compact Design, for Loads to 10 kg

- Vacuum compatible up to 10-9 hPa

- Travel ranges from 26 to 102 mm (1" to 4")

- Repeatability to 0.1 µm

- DC gear motor, stepper motor

- Direction-sensing reference switch

- Multi-axis setups possible

Please note that at the moment only a limited selelction of variants of this product family is available. This selection can be found here on the web page. The complete list of products can be found in the PDF datasheet that is available for download.

If you require further information contact us via info@pi.ws.

Product overview

High travel accuracy and load capacity due to crossed roller guides with anti-creep system. Precision ball screw with 1 mm pitch. Compact design. Stress-relieved aluminum base for high stability. Limit switch. Noncontact optical reference switch with direction sensing in the middle of the travel range.

Reduced outgassing especially for use in vacuum environments

Most notably, for the lubrication of the guides and the spindle a material with particularly low outgassing is used. This allows a bakeout temperature of up to 80° C. With this and other modifications of the PI V6 vacuum class, this positioner can be used up to 10-6 hPa.

Higher quality for applications in high vacuum

In this case, special components suitable for high vacuum are used, such as motor, measuring system, and limit switches. In addition, the surface is made of uncoated aluminum and the spindles and guides are made of stainless steel. With this, the PI V7 vacuum class is reached, which means up to 10-7 hPa.

The highest quality for special requirements in ultrahigh vacuum

In this vacuum class, the product is optimized in all details thanks to components suitable for ultrahigh vacuum in order to reach PI V9 vacuum class up to 10-9 hPa. Among other things, only selected types of plastic are used for this purpose and bakeout temperatures of 120 °C with measuring system, respectively 150 °C without measuring system are applied.

Motor types available

- DC motor with gearhead for high torques and resolution at low motor power, to 10-6 hPa

- 2-phase stepper motor for low velocity and high resolution, to 10-9 hPa

Types of position measuring

- Without encoder (open loop)

- Integrated rotary encoder on the motor shaft

Application fields

Vacuum chambers. Research. Beamline instrumentation. Microscopy. Electronics assembly and inspection.

Specifications

Specifications

| Motion | L-509.021100V6 | L-509.031100V6 | L-509.051100V6 | L-509.024132V6 | L-509.034132V6 | L-509.054132V6 | L-509.021300V7 | L-509.031300V7 | L-509.051300V7 | L-509.031600V9 | L-509.051600V9 | Tolerance |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Active axes | X | X | X | X | X | X | X | X | X | X | X | |

| Travel range in X | 26 mm | 52 mm | 102 mm | 26 mm | 52 mm | 102 mm | 26 mm | 52 mm | 102 mm | 52 mm | 102 mm | |

| Maximum velocity in X, unloaded | 10 mm/s | 10 mm/s | 10 mm/s | 1.5 mm/s | 1.5 mm/s | 1.5 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | |

| Straightness (Linear crosstalk in Y with motion in X) | ± 2 µm | ± 4 µm | ± 8 µm | ± 2 µm | ± 4 µm | ± 8 µm | ± 2 µm | ± 4 µm | ± 8 µm | ± 4 µm | ± 8 µm | typ. |

| Flatness (Linear crosstalk in Z with motion in X) | ± 2 µm | ± 4 µm | ± 8 µm | ± 2 µm | ± 4 µm | ± 8 µm | ± 2 µm | ± 4 µm | ± 8 µm | ± 4 µm | ± 8 µm | typ. |

| Pitch (Rotational crosstalk in θY with motion in X) | ± 60 µrad | ± 90 µrad | ± 120 µrad | ± 60 µrad | ± 90 µrad | ± 120 µrad | ± 60 µrad | ± 90 µrad | ± 120 µrad | ± 90 µrad | ± 120 µrad | typ. |

| Yaw (Rotational crosstalk in θZ with motion in X) | ± 60 µrad | ± 90 µrad | ± 120 µrad | ± 60 µrad | ± 90 µrad | ± 120 µrad | ± 60 µrad | ± 90 µrad | ± 120 µrad | ± 90 µrad | ± 120 µrad | typ. |

| Positioning | L-509.021100V6 | L-509.031100V6 | L-509.051100V6 | L-509.024132V6 | L-509.034132V6 | L-509.054132V6 | L-509.021300V7 | L-509.031300V7 | L-509.051300V7 | L-509.031600V9 | L-509.051600V9 | Tolerance |

| Minimum incremental motion in X | 0.1 µm | 0.1 µm | 0.1 µm | 0.1 µm | 0.1 µm | 0.1 µm | 0.1 µm | 0.1 µm | 0.1 µm | 0.1 µm | 0.1 µm | typ. |

| Unidirectional repeatability in X | ± 0.3 µm | ± 0.3 µm | ± 0.3 µm | ± 0.1 µm | ± 0.1 µm | ± 0.1 µm | ± 0.3 µm | ± 0.3 µm | ± 0.3 µm | ± 0.3 µm | ± 0.3 µm | typ. |

| Limit switches | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Forked photoelectric sensor, N/C contact, 5 V, NPN | Mechanical | Mechanical | Mechanical | Mechanical | Mechanical | |

| Motor encoder | Incremental rotary encoder | Incremental rotary encoder | Incremental rotary encoder | |||||||||

| Motor encoder: Sensor signal | A/B quadrature, RS-422 | A/B quadrature, RS-422 | A/B quadrature, RS-422 | |||||||||

| Drive Properties | L-509.021100V6 | L-509.031100V6 | L-509.051100V6 | L-509.024132V6 | L-509.034132V6 | L-509.054132V6 | L-509.021300V7 | L-509.031300V7 | L-509.051300V7 | L-509.031600V9 | L-509.051600V9 | Tolerance |

| Drive type | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | DC gear motor | DC gear motor | DC gear motor | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | |

| Nominal voltage | 24 V | 24 V | 24 V | 12 V | 12 V | 12 V | 24 V | 24 V | 24 V | 24 V | 24 V | |

| Peak voltage | 48 V | 48 V | 48 V | 48 V | 48 V | 48 V | 48 V | 48 V | ||||

| Maximum power consumption | 10 W | 10 W | 10 W | 10 W | 10 W | 10 W | 10 W | 10 W | ||||

| Motor resolution | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | ||||

| Drive force in positive direction of motion in X | 60 N | 60 N | 60 N | 60 N | 60 N | 60 N | 60 N | 60 N | 60 N | 60 N | 60 N | typ. |

| Drive force in negative direction of motion in X | 60 N | 60 N | 60 N | 60 N | 60 N | 60 N | 60 N | 60 N | 60 N | 60 N | 60 N | typ. |

| Resistance phase-phase | 3.3 Ω | 3.3 Ω | 3.3 Ω | 4.09 Ω | 4.09 Ω | 4.09 Ω | 1.7 Ω | 1.7 Ω | 1.7 Ω | 1.7 Ω | 1.7 Ω | typ. |

| Inductance phase-phase | 2.8 mH | 2.8 mH | 2.8 mH | 0.18 mH | 0.18 mH | 0.18 mH | 3 mH | 3 mH | 3 mH | 3 mH | 3 mH | |

| Back EMF, phase-phase, rotational | 1.68 V/kRPM | 1.68 V/kRPM | 1.68 V/kRPM | max. | ||||||||

| Mechanical Properties | L-509.021100V6 | L-509.031100V6 | L-509.051100V6 | L-509.024132V6 | L-509.034132V6 | L-509.054132V6 | L-509.021300V7 | L-509.031300V7 | L-509.051300V7 | L-509.031600V9 | L-509.051600V9 | Tolerance |

| Permissible push force in Y | 50 N | 50 N | 50 N | 50 N | 50 N | 50 N | 50 N | 50 N | 50 N | 50 N | 50 N | max. |

| Permissible push force in Z | 100 N | 100 N | 100 N | 100 N | 100 N | 100 N | 100 N | 100 N | 100 N | 100 N | 100 N | max. |

| Permissible torque in θx | 30 N·m | 30 N·m | 30 N·m | 30 N·m | 30 N·m | 30 N·m | 30 N·m | 30 N·m | 30 N·m | 30 N·m | 30 N·m | max. |

| Permissible torque in θY | 25 N·m | 25 N·m | 25 N·m | 25 N·m | 25 N·m | 25 N·m | 25 N·m | 25 N·m | 25 N·m | 25 N·m | 25 N·m | max. |

| Permissible torque in θZ | 20 N·m | 20 N·m | 20 N·m | 20 N·m | 20 N·m | 20 N·m | 20 N·m | 20 N·m | 20 N·m | 20 N·m | 20 N·m | max. |

| Holding force in X, passive | 50 N | 50 N | 50 N | 50 N | 50 N | 50 N | 50 N | 50 N | 50 N | 30 N | 30 N | |

| Moved mass in X, unloaded | 220 g | 220 g | 220 g | 220 g | 220 g | 220 g | 220 g | 220 g | 220 g | 220 g | 220 g | |

| Drive screw type | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | |

| Drive screw pitch | 1 mm | 1 mm | 1 mm | 1 mm | 1 mm | 1 mm | 1 mm | 1 mm | 1 mm | 1 mm | 1 mm | |

| Guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | Crossed roller guide | |

| Overall mass | 1400 g | 1500 g | 1700 g | 1100 g | 1200 g | 1500 g | 1000 g | 1100 g | 1600 g | 1400 g | 1600 g | |

| Material | Aluminum, steel | Aluminum, steel | Aluminum, steel | Aluminum, steel | Aluminum, steel | Aluminum, steel | Aluminum, steel | Aluminum, steel | Aluminum, steel | Aluminum, steel | Aluminum, steel | |

| Gear ratio i | 2401 : 81 | 2401 : 81 | 2401 : 81 | |||||||||

| Miscellaneous | L-509.021100V6 | L-509.031100V6 | L-509.051100V6 | L-509.024132V6 | L-509.034132V6 | L-509.054132V6 | L-509.021300V7 | L-509.031300V7 | L-509.051300V7 | L-509.031600V9 | L-509.051600V9 | Tolerance |

| Operating temperature range | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | |

| Vacuum class | 10⁻⁶ hPa | 10⁻⁶ hPa | 10⁻⁶ hPa | 10⁻⁶ hPa | 10⁻⁶ hPa | 10⁻⁶ hPa | 10⁻⁷ hPa | 10⁻⁷ hPa | 10⁻⁷ hPa | 10⁻⁹ hPa | 10⁻⁹ hPa | |

| Maximum bake out temperature | 80 °C | 80 °C | 80 °C | 80 °C | 80 °C | 80 °C | 80 °C | 80 °C | 80 °C | 150 °C | 150 °C | |

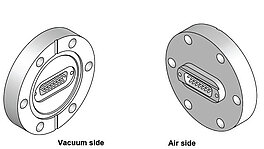

| Connector | HD D-sub 26-pin (m) | HD D-sub 26-pin (m) | HD D-sub 26-pin (m) | HD D-sub 26-pin (m) | HD D-sub 26-pin (m) | HD D-sub 26-pin (m) | D-sub 15-pole (f) | D-sub 15-pole (f) | D-sub 15-pole (f) | D-sub 15-pole (f) | D-sub 15-pole (f) | |

| Cable length | 2 m | 2 m | 2 m | 2 m | 2 m | 2 m | 2 m | 2 m | 2 m | 2 m | 2 m | |

| Recommended controllers / drivers | C-663.12 C-885 with C-663.12C885 G-901 G-910 ACS modular controller | C-663.12 C-885 with C-663.12C885 G-901 G-910 ACS modular controller | C-663.12 C-885 with C-663.12C885 G-901 G-910 ACS modular controller | C-863 C-885 with C-863.20C885 C-884 G-901 G-910 ACS modular controller | C-863 C-885 with C-863.20C885 C-884 G-901 G-910 ACS modular controller | C-863 C-885 with C-863.20C885 C-884 G-901 G-910 ACS modular controller | C-663.12 C-885 with C-663.12C885 G-901 G-910 ACS modular controller | C-663.12 C-885 with C-663.12C885 G-901 G-910 ACS modular controller | C-663.12 C-885 with C-663.12C885 G-901 G-910 ACS modular controller | C-663.12 C-885 with C-663.12C885 G-901 G-910 ACS modular controller | C-663.12 C-885 with C-663.12C885 G-901 G-910 ACS modular controller |

Downloads

Datasheet

Documentation

User Manual MP186

This document describes the following precision linear positioner, vacuum-compatible 1 E-7 hPa: L-509.0x1300V7; L-509.0x1311V7

User Manual L509T0018

L-509 Vacuum-Compatible Precision Linear Positioner (1E-9 hPa)

User Manual MP174

L-509 Vacuum-Compatible Precision Linear Stage (1 E-6 hPa)

3D Models

3-D model-L-509.0x1100V6

3-D model-L-509.0x1300V7

3-D model-L-509.0x1311V7

3-D model-L-509.0x1600V9

3-D model-L-509.0x4132V6

3-D model L-509.054132V6

3-D model L-509.051600V9

3-D model L-509.051100V6

3-D model L-509.034132V6

3-D model L-509.031600V9

3-D model L-509.031300V7

3-D model L-509.031100V6

3-D model L-509.024132V6

3-D model L-509.021600V9

3-D model L-509.021300V7

3-D model L-509.0513xxV7

3-D model L-509.0211xxV6

Quote / Order

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

Vacuum-compatible precision linear stage; 2-phase stepper motor; 52 mm travel range; 100 N load capacity; 10 mm/s maximum velocity; ball screw; vacuum compatible to 10⁻⁶ hPa

Vacuum-compatible precision linear stage; 2-phase stepper motor; 102 mm travel range; 100 N load capacity; 10 mm/s maximum velocity; ball screw; vacuum compatible to 10⁻⁶ hPa

Vacuum compatible precision linear stage; DC gear motor; 26 mm travel range; 100 N load capacity; 1.5 mm/s maximum velocity; ball screw; incremental rotary encoder; A/B quadrature, RS-422; vacuum compatible to 10⁻⁶ hPa

Vacuum-compatible precision linear stage; DC gear motor; 52 mm travel range; 100 N load capacity; 1.5 mm/s maximum velocity; ball screw; incremental rotary encoder; A/B quadrature, RS-422; vacuum compatible to 10⁻⁶ hPa

Vacuum compatible precision linear stage; DC gear motor; 102 mm travel range; 100 N load capacity; 1.5 mm/s maximum velocity; ball screw; incremental rotary encoder; A/B quadrature, RS-422; vacuum compatible to 10⁻⁶ hPa

Vacuum-compatible precision linear stage; 2-phase stepper motor; 26 mm travel range; 100 N load capacity; 10 mm/s maximum velocity; ball screw; vacuum compatible to 10⁻⁷ hPa; 2 m cable length

Vacuum-compatible precision linear stage; 2-phase stepper motor; 52 mm travel range; 100 N load capacity; 10 mm/s maximum velocity; ball screw; vacuum compatible to 10⁻⁷ hPa; 2 m cable length

Vacuum-compatible precision linear stage; 2-phase stepper motor; 102 mm travel range; 100 N load capacity; 10 mm/s maximum velocity; ball screw; vacuum compatible to 10⁻⁷ hPa; 2 m cable length

Vacuum-compatible precision linear stage; 2-phase stepper motor; 52 mm travel range; 100 N load capacity; 10 mm/s maximum velocity; ball screw; vacuum compatible to 10⁻⁹ hPa; 2 m cable length

Vacuum-compatible precision linear stage; 2-phase stepper motor; 102 mm travel range; 100 N load capacity; 10 mm/s maximum velocity; ball screw; vacuum compatible to 10⁻⁹ hPa; 2 m cable length

Ask an engineer!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.

Technology

Vacuum

Careful handling, adequate premises: PI does not only have the necessary equipment for the qualification of materials, components and final products, but also has many years of experience with regard to HV und UHV positioning systems.

Rotating Electric Motors

Rotating electric motors such as DC or stepper motors are used in connection with screw or worm drives.