P

Patents

Parallel Kinematics, Hexapods

Parallel-Kinematic Piezo Stages

Parallel Metrology

Peak Current

PICA / PICA Power

PICMA® Multilayer Piezo Actuators

PICMAWalk

Piezoelectric Inertia Drive

PiezoMove®

Piezoresistive Sensor (PRS)

PIglide Air Bearing Technology

PILine® Ultrasonic Piezomotors

PIMag® Magnetic Linear Motors

PIMag® Voice Coil

Pivot Point

PIRest

Pitch

Planetary Gears

Power Consumption

Preloaded Piezo Actuator

Profile Generator

Pulse Width Modulation (PWM)

Push/Pull Force Capacity (in Positioning Direction)

PZT

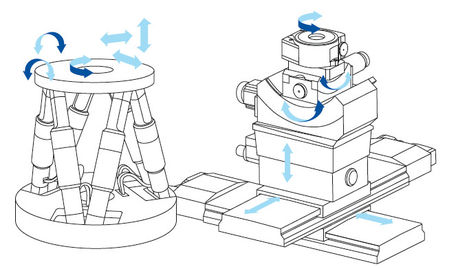

Parallel Kinematics, Hexapods

Hexapods are parallel-kinematic systems with six drives that are connected directly to a single platform. This makes it possible for users to position objects automatically in all degrees of freedom, X, Y, Z, and rotatory and, depending on the drive, with an accuracy in the micrometer range or lower. The parallel-kinematic system is very stiff, with only a low passive weight to move and, with the corresponding design, can carry loads up to several tons. Users are able to arbitrarily choose the reference coordinate system and, today, workers are now working together with hexapods on the production line. The user integrates the system into the automation environment via EtherCAT.

Parallel-Kinematic Piezo Stages

Piezo stages reach optimum trajectory accuracy with a parallel-kinematic setup that uses capacitive sensors for parallel measuring. All actuators act directly on one motion platform in a parallel-kinematics, multi-axis system. This means that all axes move the same minimized mass and can be designed with identical dynamic properties. Parallel-kinematic systems have additional advantages over serially stacked systems, including more compact construction and no cumulative errors from the individual axes. Multi-axis nanopositioning systems equipped with direct metrology are able to measure platform position in all degrees of freedom against one common reference. In such systems, undesirable motion from one actuator in the direction of another (crosstalk) is detected immediately and actively compensated by the servo loops. This active trajectory control concept can keep deviation from a trajectory to under a few nanometers, even in dynamic operation.

Parallel Metrology

Each sensor measures the position of the same motion platform in the respective degree of freedom. This keeps crosstalk of all axes inside the servo loop and allows it to be corrected automatically.

Peak Current

Available only for short periods of time, typically less than a few millisecond in the case of piezo amplifiers/controllers. It is used to estimate the possible dynamics with a certain capacitive load. Note: In this case, the piezo controller/ driver does not necessarily work linearly.

PICA / PICA Power

PICA piezo actuators are specifically designed for high duty cycle applications. PICA Power actuators are additionally optimized for high-temperature working conditions.

All materials used are specifically matched for robustness and lifetime. Endurance tests on PICA drives proved consistent performance, even after billions (1,000,000,000 ) of cycles. The combination of high displacement and low electrical capacitance provides for excellent dynamic behavior with reduced driving power requirements.

PICMA® Multilayer Piezo Actuators

PICMA® actuators take advantage of the indirect piezoelectric effect and achieve high forces with relatively low voltages. They only need a small amount of installation space. At the same time, the PICMA® actuators are very dynamic and can reach a position with a hitherto unattained precision. This is the reason why they are used as micropump applications in metering technology. Due to their ceramic insulation, PICMA® actuators exhibit high reliability and climate resistance. PI also equips PICMA® actuators with individual connectors for customer applications.

PICMAWalk

PICMAWalk drives achieve feed forces up to 50 N and holding forces to 60 N. The maximum velocity is 15 mm/s. PICMAWalk uses the proven PICMA multilayer piezo actuators. That means lower piezo control voltages to 120 V. PICMA® piezo actuators also ensure a long lifetime and the outstanding reliability of the PICMAWalk technology.

Piezoelectric Inertia Drive

Piezo inertia drives are space-saving and affordable piezo-based drives with relatively high holding forces and a theoretically unlimited travel range. The drives acting directly on the runner achieve velocities of more than 5 mm/s with an operating frequency of max. 20 kHz. The Q-Motion drive runs silently at an operating frequency of 20 kHz. The drive is self-locking at rest, requires no current, and does not generate any heat. It holds the position with maximum force. It is therefore suitable for battery-powered, mobile applications with a low number of load cycles.

PiezoMove®

PiezoMove® actuators combine guided motion with long travel ranges up to 1 mm as well as an optional sensor which provides precision up to 10 nanometers. The high-precision, frictionless flexure guides achieve very high stiffness as well as extremely low lateral displacement.

This makes them easier to handle than a simple piezo actuator, but still keeps them extremely compact. The number and size of the piezo actuators used determine stiffness and force generation. Due to these features, their small dimensions and the inexpensive design, the PiezoMove® lever actuators are particularly suitable for OEM applications.

PiezoWalk® Walking Drive

PiezoWalk® drives take advantage of the piezo walking principle and combine subnanometer resolution with high forces, a robust design, and a scalable travel range. Industry customers use walking drives for travel ranges greater than 1 mm and to hold a stable position with nanometer precision resolution. PI (Physik Instrumente) offers walking drives with high feed forces as well as positioning and holding forces, but also relatively high velocities, and they also have a long lifetime in a vacuum.

See >> NEXLINE®, >> NEXACT®, and >> PICMAWalk.

PIglide Air Bearing Technology

The PIglide air bearing technology allows friction-free positioning with a high guiding accuracy up to 5 µrad over 100 mm. This technology improves the position resolution and makes it possible to realize constant-velocity scanning. The repeatability is only a few encoder impulses. A similar precision in the nanometer range is also possible with flexure-guided piezo nanopositioners, however, only over considerably shorter travel ranges.

PILine® Ultrasonic Piezomotors

PILine® Ultrasonic piezo motors are precise, dynamic, small, and noiseless, and are also self-locking. As a result, they don’t have to be supplied with current when at rest and that, in turn, reduces the energy requirements of the application. For this reason and due to their small size, the drives are very popular for mobile devices in the optical industry and measuring technology where they can replace classical drive technology.

PIMag® Magnetic Linear Motors

Magnetic direct drives from PI (Physik Instrumente) provide a direct and stiff connection between the load to be moved and the drive. The industry demand is particularly high when objects need to be positioned with high dynamics and precision. Thanks to the smooth-running precision linear guides with crossed roller bearings, these types of linear motor stages are particularly suitable for applications that require constant-velocity scanning. The drives operate without contact and therefore very reliable. Users can integrate the magnetic direct drives into existing machines and systems quickly and easily via standardized fieldbus systems.

PIMag® Voice Coil

Thanks to their low weight and friction-free drive principle, voice coil drives are small and particularly suitable for applications that require high dynamics and high velocities over limited travel ranges - for example, in medical technology. Voice coil drives have a greater advantage for the customer when compared to traditional drive screw-based solutions, particularly with respect to wear and dynamics. High scan frequencies and precision positioning are possible with these drives, because they are free of hysteresis effects.

See >> Voice Coil Drive.

PIMikroMove

User software with graphical user interface (GUI) for controlling positioning systems from PI, irrespective of their drive principle.

PIRest

Piezo actuator technology for active adjustment of consistently stable gaps of several micrometers with subnanometer precision. The PIRest actuator is only powered during the actual positioning sequence and holds its position without power.

Pitch

See >> Crosstalk.

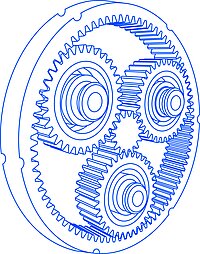

Planetary Gears

Planetary gears consist of a central sun wheel connected to a shaft, and other planet wheels that are located within a ring wheel. They are suitable for transferring the highest torque because the load is distributed via several toothed wheels. In this manner, high gear ratios can be realized in very compact assembly spaces. Often, the input stage's toothed wheels are made of a synthetic material to reduce high speed noises. For applications in vacuum, high temperatures or for very high torques, the input stage is preferably made of steel. In addition to spur gears, planetary gears are generally used for the gear motors in PI's linear stages.

Preloaded Piezo Actuator

Piezoelectric stack actuators are protected by an internal preload. The preload ensures a safe operation in any kind of application scenario and is ideal for dynamic applications and for tensile loads as well. Preloaded piezo actuators are intended for integration into a customer’s system and have no guides. An external guide is required if motion crosstalk in individual axes cannot be tolerated.

Profile Generator

Functionality of motor controllers that allows motion profiles such as linear interpolation, point-to-point, trapezoid, and double bends. Several axes are referred to as an electronic gear function.

Pulse Width Modulation (PWM)

PWM-controlled motors allow control of the (motor) performance with a high-frequency-signal. This means that the power signal can be separated from the digital control signal.

PWM controllers are used for example, with high-performance switching amplifiers for piezo actuators, or for controlling electric motors such linear motors or voice coil drives. The >> ActiveDrive Motor is a special feature from PI, see there.

Push/Pull Force Capacity (in Positioning Direction)

Specifies the maximum forces that can be applied to the piezo system along the active axis. Limited by the piezoelectric material and the flexure. If larger forces are applied, the piezo actuator, the flexures or the sensor could be damaged. Limiting the force must be considered in dynamic applications.

Example: the dynamic forces generated by sinusoidal operation at 500 Hz, 20 µm peak-to-peak, 1 kg moved mass, are approximately ±100 N.