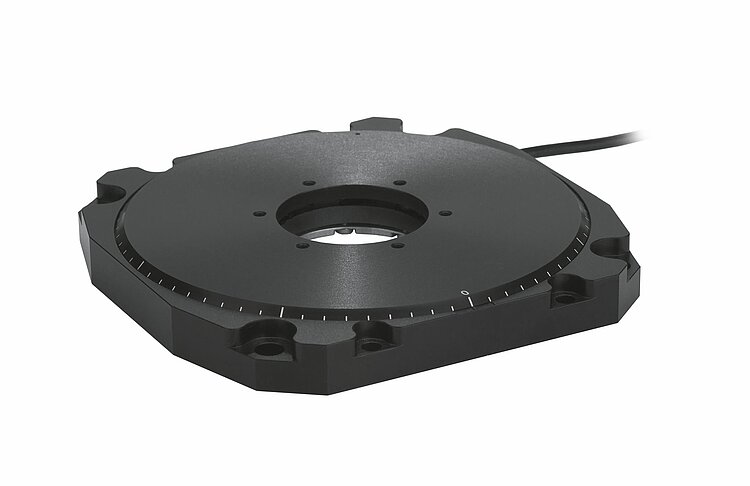

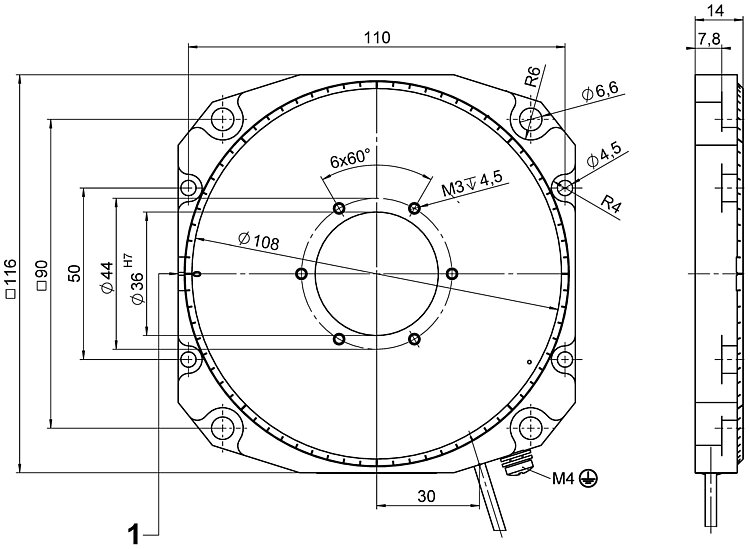

PILine® rotation stage with low-profile design; PILine® piezo motor, performance class 2; >360 ° rotational angle; 20 N load capacity; 540 °/s maximum angular velocity; incremental angle measuring system, 9 µrad sensor resolution; 1.5 m cable length

U-651 Rotation Stage with Low-Profile Design

Fast PILine® Direct Drive and Central Opening

- Low profile of only 14 mm

- Positions larger loads quickly and with precision

- Unlimited rotation range >360°

- Drive torque to 0.3 Nm in both directions of rotation

- Self-locking when switched off: saves energy and reduces generation of heat

- Central aperture for more fields of application

Precision-class rotation stage

PILine® stages are particularly suitable for applications that require fast precision positioning. When switched off, the self-locking drive holds the position of the stage mechanically stable. Energy consumption and heat generation are therefore considerably reduced. Applications with a low duty cycle that are battery-powered or heat-sensitive benefit from these characteristics. The position of the axis is measured by an encoder and an optical reference switch allows reliable repeatable motion. The piezomotor drive principle and its electrical operation are inexpensive and can be customized.

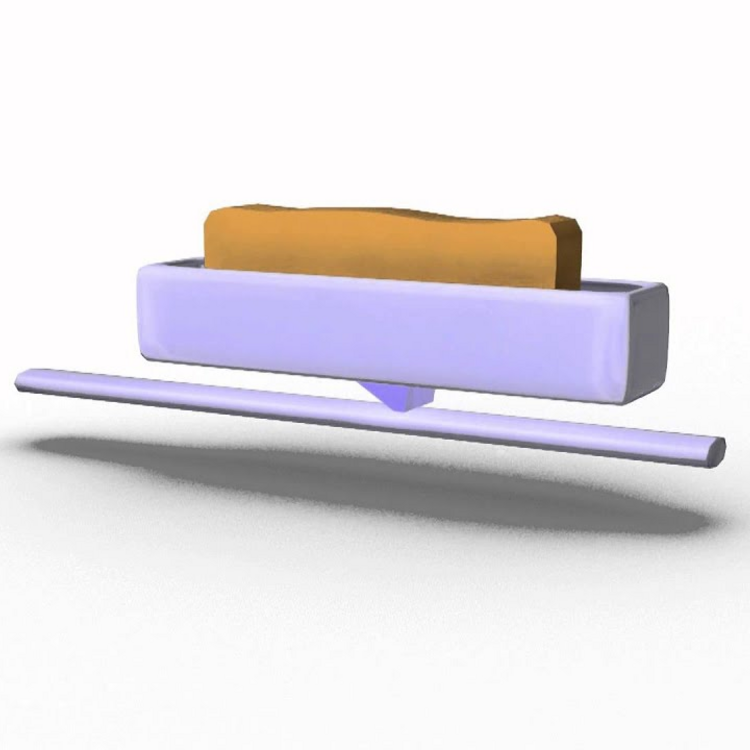

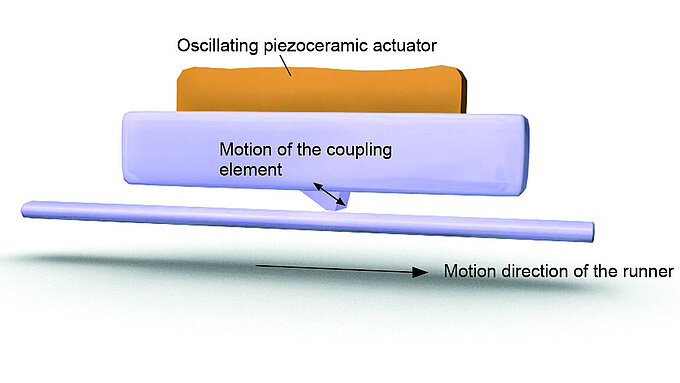

PILine® ultrasonic piezomotors

An integral part of a PILine® ultrasonic piezomotor is a piezo actuator that is preloaded against a movable, guided runner via a coupling element. The piezoceramic actuator is excited to ultrasonic oscillation by a high-frequency AC voltage between 100 and 200 kHz. Deformation of the actuator leads to periodic diagonal motion of the coupling element relative to the runner. The feed created is a few nanometers per cycle; the high frequencies lead to the high velocities. Preloading the piezoceramic actuator against the runner ensures self-locking of the drive when at rest and switched off.

Highly accurate position measuring with incremental encoder

Noncontact optical encoders measure the position directly at the platform with the greatest accuracy. Nonlinearity, mechanical play, or elastic deformation have no influence on the measurement.

Crossed roller guide

With crossed roller guides, the point contact of the balls in ball guides is replaced by line contact of the hardened rollers. Consequently, they are considerably stiffer and need less preload, which reduces friction and allows smoother running. Crossed roller guides are also distinguished by high guiding accuracy and load capacity. Force-guided rolling element cages prevent cage creep.

Application fields

Micromanipulation, automation, biotechnology, sample manipulation, sample positioning, optical metrology.

Specifications

Specifications

| Motion | U-651.03 | U-651.04 | Tolerance |

|---|---|---|---|

| Active axes | θZ | θZ | |

| Rotation range in θZ | > 360 ° | > 360 ° | |

| Maximum angular velocity in θZ | 540 °/s | 540 °/s | |

| Positioning | U-651.03 | U-651.04 | Tolerance |

| Minimum incremental motion in θZ | 27 µrad | 12 µrad | typ. |

| Bidirectional repeatability in θZ | 108 µrad | 48 µrad | typ. |

| Reference switch | Optical | Optical | |

| Integrated sensor | Incremental angle-measuring system | Incremental angle-measuring system | |

| Sensor resolution, rotational | 9 µrad | 4 µrad | |

| Drive Properties | U-651.03 | U-651.04 | Tolerance |

| Drive type | PILine® piezo motor, performance class 2 | PILine® piezo motor, performance class 2 | |

| Drive torque clockwise in θZ | 0.3 N·m | 0.3 N·m | max. |

| Drive torque counterclockwise in θZ | 0.3 N·m | 0.3 N·m | max. |

| Mechanical Properties | U-651.03 | U-651.04 | Tolerance |

| Permissible push force in Z | 20 N | 20 N | max. |

| Holding torque in θZ, passive | 0.3 N·m | 0.3 N·m | min. |

| Bearing type | Crossed roller bearings | Crossed roller bearings | |

| Overall mass | 500 g | 500 g | ±5 % |

| Material | Anodized aluminum | Anodized aluminum | |

| Miscellaneous | U-651.03 | U-651.04 | Tolerance |

| Operating temperature range | 0 to 40 °C | 0 to 40 °C | |

| Connector | D-sub 15-pin (m) | D-sub 15-pin (m) | |

| Cable length | 1.5 m | 1.5 m | |

| Recommended controllers / drivers | C-867.1U, C-867.10C885, C-867.2U2 | C-867.1U, C-867.10C885, C-867.2U2 |

Cable length:

Tolerance with cable length 1.5 m: +200 mm / -0 mm

Downloads

Datasheet

Documentation

User Manual MP136

U-651 PILine® Rotation Stage

3-D Models

U-651 3-D model

Quote / Order

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

PILine® rotation stage with low-profile design; PILine® piezo motor, performance class 2; >360 ° rotational angle; 20 N load capacity; 540 °/s maximum angular velocity; incremental angle measuring system, 4 µrad sensor resolution; 1.5 m cable length