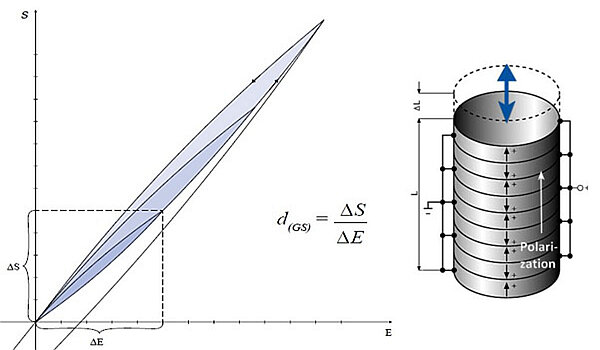

The >> principle is relatively simple: the extension of the stack changes roughly proportional to the drive voltage, with typical strain on the order of 0.1% of the stack’s length available. Charging and discharging of a piezo actuator is related to charging and discharging an electric capacitor.

Quasi-Static Applications

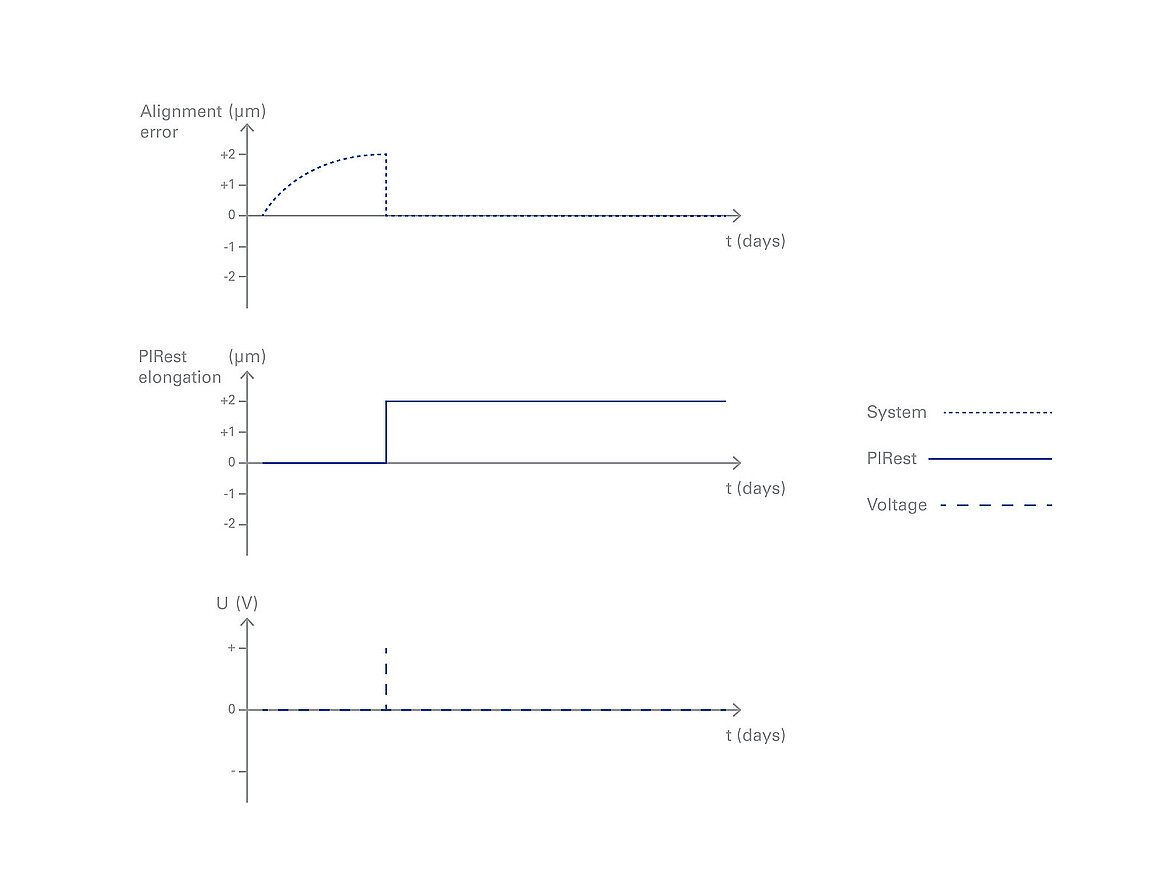

When static applications are concerned, i.e. several parts are to be aligned and held in place, piezo actuators work well, and their atomic-level resolution is welcome in many optics, laser and semiconductor related applications. However, each actuator will require a driver to maintain the required position. When the voltage source is removed, the piezo stack will slowly discharge and whatever dimensional change was affected by charging it will disappear.

Programmable Shims

Programmable Shims

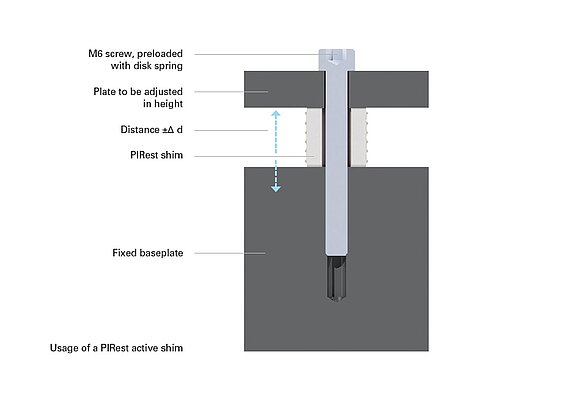

A new technology, also based on the piezo effect, can be utilized in situations where high resolution and stability are crucial, but a continuous drive voltage is unwanted and accessibility for manual adjustment is not possible.

Applications for programmable (semi-active) shims can be found where the alignment between two or more subassemblies is critical and realignment may be required at some point due to environmental changes, creep or settling processes, etc.

Examples

Specifications

A variety of standard programmable shims are available as listed in the table below. Custom versions are possible.

* TH: Tower height OD: Outer diameter ID: Inner diameter

| Dimensions* in mm | Displacement in μm | Tolerance of total displacement | |

| OD × ID × TH | |||

|

PIRest Multilayer Ring Piezo Shim (with inner hole) |

8 × 4.5 × 8.5 8 × 4.5 × 16 8 × 4.5 × 36 |

2.9 5.8 13.3 |

±20 % ±20 % ±20 % |

| OD × TH | |||

|

PIRest Round Multilayer Piezo Shim (without inner hole, high blocking Force) |

16 × 16 16 × 36 16 × 17 |

7.4 17 37.1 |

–10 % / ±20 % –10 % / ±20 % –10 % / ±20 % |

| A × B × TH | |||

|

PIRest Multilayer Piezo Shim (ceramic-insulated high power) |

3 × 2 × 9 up to 10 × 10 × 36 |

3.4 up to 17 |

±10 % ±10 % |

| OD × TH | |||

|

PIRest Encapsulated Piezo Shim (For harsh industrial environments) |

11.2 × 22.5 11.2 × 40.5 18.6 × 22.5 |

7.4 15.9 7.4 |

±10 % ±10 % ±10 % |

| OD × ID × TH | |||

|

PIRest Chip Shim (miniature with and without inner hole) |

5 × 2.5 × 2.5 up to 16 × 8 × 2.5 |

1.06 up to 1.2 |

±20 % ±20 % |

| A × B × TH | |||

| PIRest Chip Shim (miniature multilayer piezo actuators) |

2 × 2 × 2 up to 10 × 10 × 2 | 1.2 | ±20 % |